Since many of the recipes I use have come to me from the generous support of other artists or published materials I am happy to share any information others might find useful. Below, I’ve included some info about my current body of work as well as recipes that I no longer use from the two preceding bodies of work. If you have any questions about the materials or process’ please do not hesitate to contact me. Also, if you would like more comprehensive information or instruction, I have a DVD (release Nov. 2018) titled: “Unifying Form & Surface” available for purchase from Ceramic Arts Network, click here to visit their website.

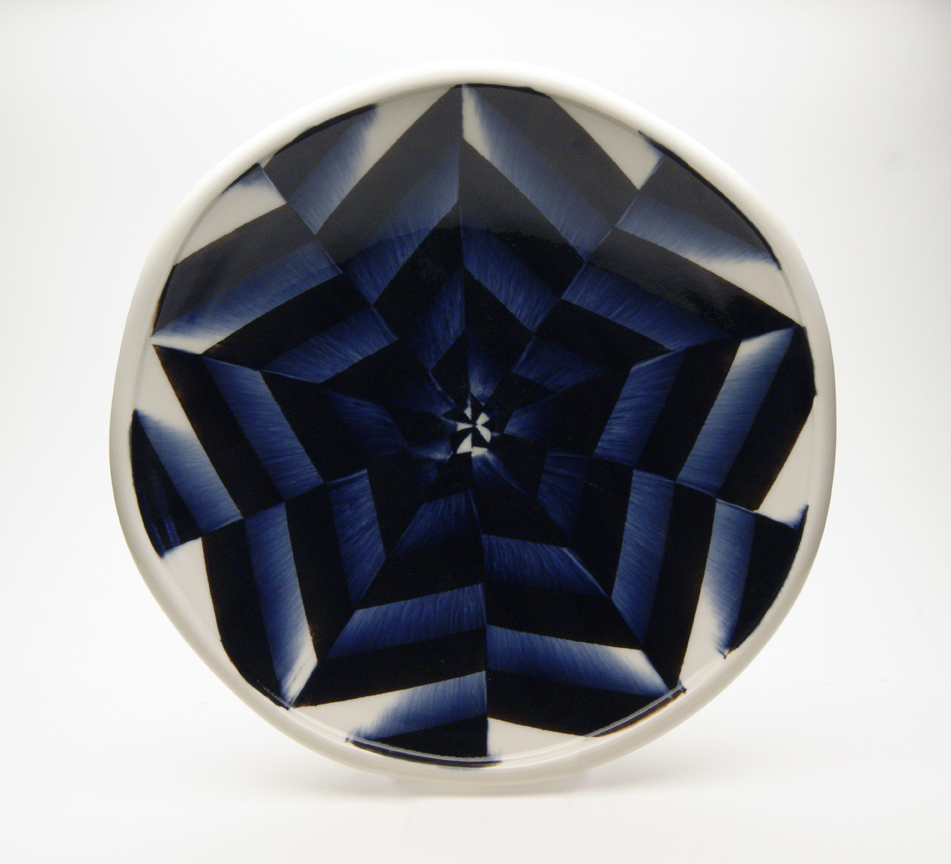

This work is a relatively new avenue of investigation for me. I began testing in 2018 and have since worked through a few iterations. At this point, my material knowledge regarding this work is still in the learning phase, so I won’t be publishing any recipes for sometime.

However, I can offer a brief description . . . essentially this work is made using an iron-bearing high-fire stoneware clay body with a white slip applied on leather-hard clay.

Most of the decoration and brushwork are done while the piece is bone dry. Once bisqued, I apply a thin Clear Base glaze and occasionally other pigmented glaze to accentuate the form and/or design. I fire in a gas reduction kiln or sometimes a Wood Kiln to cone 10 with moderate body reduction between cone 012 – 08 and then remain in a very light reduction atmosphere to cone 10 (approx. 2350 F)

Grolleg Porcelain Body

25 Grolleg Kaolin

10 C&C Ball Clay

10 Tile #6 Kaolin

35 Minspar 200 Feldspar

20 Silica 325 Mesh

2.5 Bentonite L-10 White

*this clay body throws well, but is far superior if de-aired and pugged. It can also easily be made into a casting slip with little adjustment other than deflocculating.

Clear Glaze, Cone 5-7

11 Spodumene

21 Frit 3134

20 EPK

20 Silica

20 Wollastonite

8 Zinc Oxide

*this glaze can be quite runny when applied thickly. However, the movement is very viscous and if fired with the adjacent clay body, I recommend firing to cone 7 oxidation.

Clear Glaze Base

20 Nepheline Syenite

30 Frit 3124

10 EPK

10 Silica

4 Lithium Carbonate

Colorant Additions: (These work for both of the glazes listed above)

4% RIO – Amber

8% RIO – Dark Amber

4% Copper Carb. + 2% RIO – Warm Green

3% Copper Carb. – Turquoise

6% Copper Carb. – Emerald Green

0.5% Cobalt Carb. + 1% Manganese Diox. – Lavender

0.5% Cobalt Carb. + 1% RIO – Grey/Blue

0.25% Cobalt Carb. – Light Blue

*this is a runny glaze at cone 1, even more so if taken to cone 3.

Clear Glaze Base (mod)

20 Nepheline Syenite

30 Frit 3124

4 Lithium Carbonate

10 EPK

10 Silica (325 Mesh)

add:

3% Zinc Oxide

2% Bentonite

*the modifications to the base impart better glaze fit (addition of silica), easier raw application, as well as more fired durability (addition of Zinc)